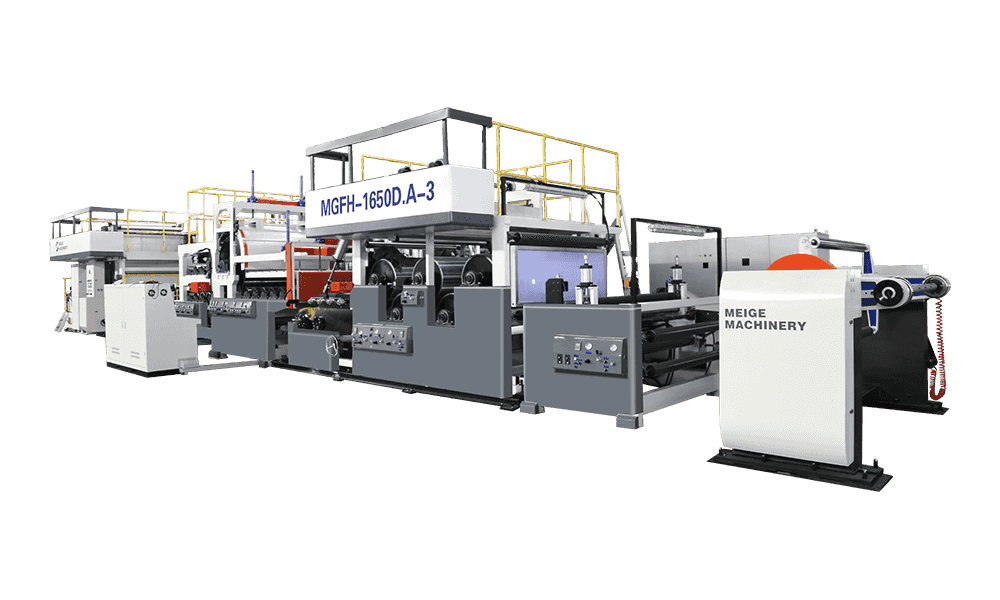

In today's highly competitive market, it is crucial to choose a PVC multi-layer laminating machine that is efficient, durable and meets production needs. As a piece of equipment involving multiple fields, production requirements, machine performance, technical support and other factors should be fully considered when purchasing. This article will explore how to choose the right PVC multi-layer laminating machine for your company.

1. Choose specifications according to production needs

Different industries have different requirements for PVC multi-layer laminating machines. Therefore, before purchasing equipment, companies should clarify production needs, including daily output, number of laminating layers, material types, etc. For example, some packaging companies may only need simple double-layer lamination, while waterproof materials in the construction industry may require more complex multi-layer lamination processes. Therefore, it is critical to ensure that the machine's capacity and performance can meet current production needs.

In addition, the width and speed of the equipment are also important criteria for selection. Large-scale production lines usually require wider equipment to improve efficiency, while some customized needs may tend to prefer small and medium-sized equipment to ensure flexibility.

2. Consider the technical configuration of the equipment

Modern PVC multi-layer laminating machines are usually equipped with advanced automation and intelligent functions. When choosing equipment, you should pay attention to whether it has the following functions:

Automatic adjustment function: Through the PLC control system, the operator can easily set parameters on the touch screen and automatically adjust key production factors such as temperature, speed, and pressure. The higher the degree of automation, the less manual intervention can be done and the higher the production efficiency.

Intelligent monitoring: Many new equipment are equipped with real-time monitoring and fault alarm functions, which can detect problems in the production process in time, avoid quality defects or equipment damage, and extend the life of the equipment.

Energy saving and environmental protection: Choosing equipment with energy-saving design can not only reduce operating costs, but also meet increasingly stringent environmental protection standards. The equipment should have energy efficiency optimization functions to reduce energy consumption.

3. Understand the manufacturer's after-sales service and technical support

After the equipment is purchased, good after-sales service and technical support are essential. Some large-scale production equipment manufacturers usually provide comprehensive after-sales services, such as equipment installation, commissioning, and regular maintenance to ensure the stable operation of the equipment in the production line. In addition, the response speed and professionalism of the technical support team also directly affect production efficiency. Therefore, choosing brands and suppliers with good after-sales service guarantees is an important factor that must be considered when purchasing PVC multi-layer composite machines.

4. Long-term use costs

In addition to the initial purchase cost, the equipment's maintenance costs, energy consumption, and spare parts replacement costs are also factors that companies need to consider comprehensively. High-quality PVC multi-layer laminating machines usually have a longer service life and lower maintenance requirements, which can help companies reduce long-term operating costs. In addition, understanding the equipment's ease of operation, failure rate, etc. is also the key to determining whether the equipment is worth investing in for the long term.