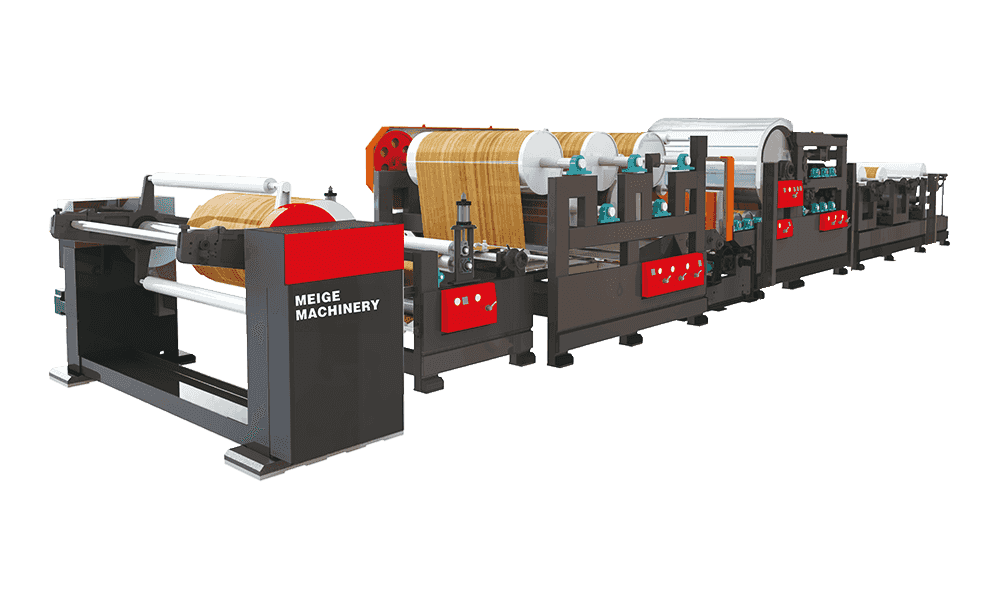

With the continuous advancement of industrial technology, PVC Multi-Layer Laminating Machine has become one of the indispensable equipment in all walks of life. It is mainly used to bond multiple layers of different materials to each other through hot pressing or other processes to form a composite material with multiple functions. In the fields of plastic packaging, building materials and automobile manufacturing, PVC multi-layer laminating machine is widely used.

Functions of PVC Multi-Layer Laminating Machine

The core function of PVC multi-layer laminating machine is to combine PVC film with other materials (such as aluminum foil, non-woven fabric or paper) into a new composite material through a multi-layer lamination process. This material can have the waterproof, moisture-proof and chemical corrosion-resistant properties of PVC, and at the same time, according to different composite requirements, it can also achieve higher strength, flexibility or aesthetics.

During operation, the heating device of the PVC multi-layer laminating machine evenly heats the material to a temperature suitable for bonding. The roller system of the machine can ensure that the material is laminated at an appropriate pressure and speed to ensure the stable quality of the final product. By adjusting the parameters, the operator can flexibly control the composite effect of different materials to meet diverse market needs.

Advantages of PVC multi-layer composite machine

Efficient production: The traditional manual composite process is inefficient and the product quality is difficult to guarantee. The PVC multi-layer composite machine greatly improves the production speed through automated operation, while reducing human errors, so that the quality of each product can meet the expected standards.

Diversified material processing capabilities: The PVC multi-layer composite machine can not only process PVC materials, but also composite a variety of other materials, such as PE, PET, aluminum foil, etc. Therefore, it is widely used in the production of various composite films to meet the needs of different customers.

Energy saving and environmental protection: Modern PVC multi-layer composite machines are usually equipped with advanced energy-saving technologies to ensure efficient production while reducing energy consumption. In addition, many composite materials do not require the use of chemical glue during the production process, which reduces the emission of harmful substances and is more environmentally friendly.

Automation and intelligence: The new PVC multi-layer composite machine is equipped with an advanced automatic control system. The operator can easily set parameters through the human-machine interface and monitor the production status in real time. This not only simplifies the operation process, but also improves the operating efficiency of the equipment and reduces downtime.

Application field

PVC multi-layer composite machine has a wide range of applications in construction, packaging, automobiles, home decoration and other fields. For example, in the construction field, PVC composite materials are often used in the production of waterproof layers or thermal insulation materials; in the packaging industry, PVC composite films are used to make high-strength, moisture-proof packaging bags; in the automotive industry, PVC composite materials are often used in the production of car interior decoration parts.