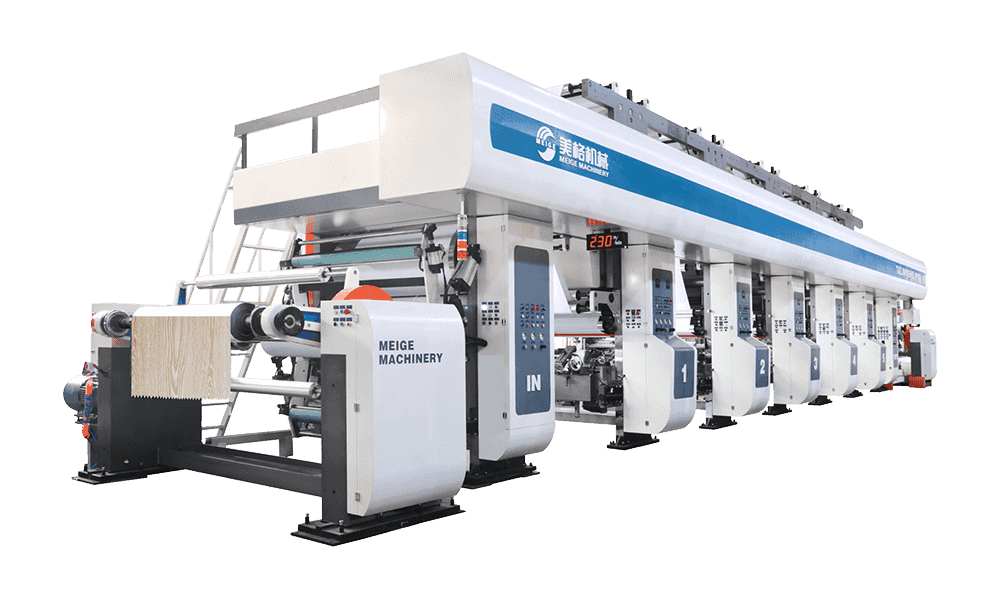

PVC gravure printing machines are vital tools in the packaging and printing industry, especially for producing high-quality printed materials on PVC substrates.

What is Gravure Printing?

Gravure printing, also known as rotogravure, is a high-speed printing technique that uses engraved cylinders to transfer ink onto a substrate. This method allows for consistent and vibrant prints, making it ideal for large production runs. The engraving on the cylinders is created through a variety of techniques, including laser etching and chemical engraving, which produces tiny cells that hold the ink.

How PVC Gravure Printing Machines Work

PVC gravure printing machines operate by feeding a PVC substrate through a series of rollers. The engraved cylinder rotates, transferring ink from the cells onto the PVC film. The process typically involves several steps:

Ink Preparation: Special inks are formulated for gravure printing, ensuring good adhesion to PVC. These inks are often solvent-based, providing excellent color vibrancy and durability.

Cylinder Preparation: The engraved cylinders are mounted onto the machine. Each cylinder corresponds to a different color, allowing for multi-color printing in a single pass.

Printing Process: As the substrate moves through the machine, it passes under the engraved cylinder. The ink is transferred onto the PVC, creating a high-resolution print.

Drying and Finishing: After printing, the substrate typically goes through a drying system, which can include hot air or UV curing, ensuring that the ink adheres properly before cutting and packaging.

Key Features of PVC Gravure Printing Machines

High Speed and Efficiency: Gravure printing machines are known for their high-speed operations, which significantly reduce production time and costs.

Versatility: These machines can handle various thicknesses of PVC and can print on other materials, such as paper and film, making them versatile tools for manufacturers.

Quality Output: The precision of gravure printing allows for sharp, clear images and vibrant colors, essential for appealing packaging designs.

Customization: Many modern PVC gravure printing machines offer advanced features like automatic registration and color control systems, enabling customization to meet specific production needs.

Applications of PVC Gravure Printing Machines

Packaging: PVC gravure printing is extensively used in packaging applications, including food packaging, shrink sleeves, and labels. The durability and moisture resistance of printed PVC make it suitable for various products.

Decorative Prints: These machines are also used for decorative printing on items such as wallpapers, gift wraps, and point-of-sale materials.

Technical Applications: Gravure printing can be employed in producing specialized products like medical packaging, where high-quality prints are critical for maintaining product integrity.

Textiles: Gravure printing is used in the textile industry for printing designs on PVC-coated fabrics, offering both aesthetic appeal and functional benefits.