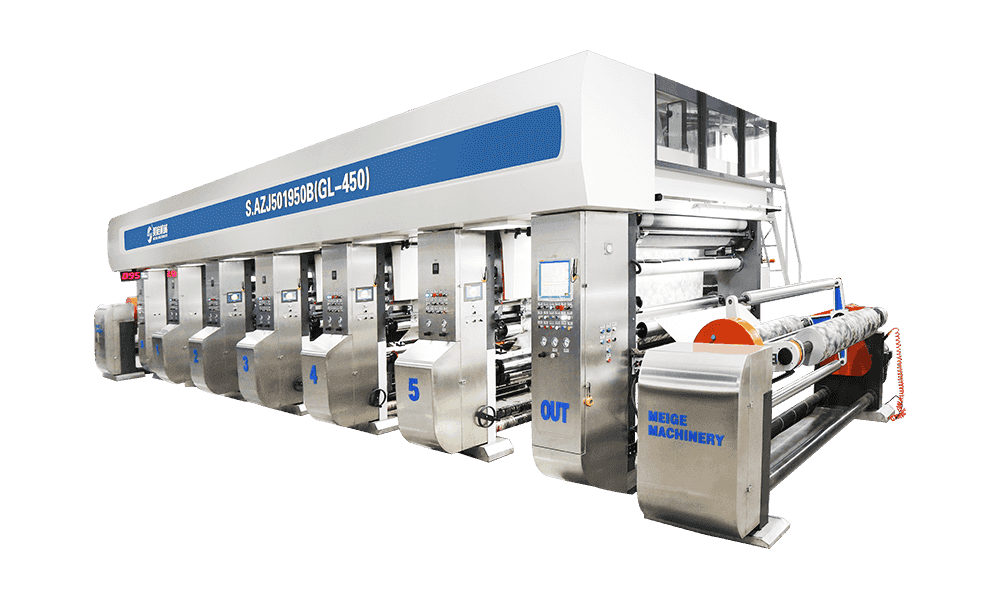

Gravure printing involves engraving an image onto a cylinder, which is then used to transfer ink onto a substrate. This process ensures exceptional print quality, even on large-scale projects. The engraved cylinders are typically made of copper or chrome, allowing for durability and fine detail reproduction. Gravure printing machines are particularly favored for their ability to handle long print runs efficiently, making them ideal for industries such as packaging, textiles, and publishing.

One of the standout features of gravure printing is its versatility. These machines can print on a wide range of materials, including paper, plastic, foil, and even fabric. This adaptability makes them a go-to choice for businesses looking to produce high-quality prints across diverse applications.

Key Considerations When Evaluating Gravure Printing Machines

When exploring gravure printing machines, several factors must be taken into account to ensure the right fit for specific needs. First and foremost is the machine's capacity for customization. Advanced models offer adjustable settings for ink viscosity, drying systems, and speed controls, allowing for precise adjustments based on the material being printed. Additionally, modern gravure machines often come equipped with automated features that streamline operations, reduce labor costs, and minimize errors.

Another important aspect is the machine's compatibility with eco-friendly practices. As sustainability becomes a priority across industries, many gravure printing machines now incorporate technologies that reduce ink waste and energy consumption. This not only benefits the environment but also aligns with global trends toward greener manufacturing processes.

Comparing Gravure Printing to Letterpress Printing

While gravure printing machines excel in high-volume and detailed print jobs, it’s worth considering how they stack up against other methods, such as letterpress printing. Letterpress printing, known for its tactile impressions and artisanal appeal, has its own set of advantages, especially for short-run or specialty projects. For instance, "The top ten letterpress printing machines in China" are renowned for their craftsmanship and ability to produce unique, textured prints that gravure machines cannot replicate.

However, when it comes to efficiency and scalability, gravure printing takes the lead. Unlike letterpress, which requires individual plates for each color, gravure machines use a single engraved cylinder, significantly reducing setup time and costs for multi-color projects. This makes gravure printing machines more suitable for industries that prioritize speed and volume without compromising on quality.

Innovations in Gravure Printing Technology

Recent advancements in gravure printing technology have further enhanced its appeal. Digital integration is one such innovation, allowing for real-time monitoring and adjustments during the printing process. This not only improves accuracy but also reduces downtime caused by manual interventions. Furthermore, some of the latest gravure machines feature hybrid capabilities, combining gravure with other printing techniques like flexography or digital printing to create versatile, multi-functional systems.

Another exciting development is the integration of artificial intelligence (AI) and machine learning. These technologies enable predictive maintenance, ensuring that potential issues are addressed before they impact production. Such innovations make gravure printing machines a future-proof investment for businesses aiming to stay ahead in a competitive market.

Final Thoughts

Choosing the right printing technology depends on specific requirements, budget, and long-term goals. Gravure printing machines shine in scenarios that demand high-speed, high-quality output, while methods like letterpress remain unmatched for their artistic touch. By understanding the strengths and limitations of each option, informed decisions can be made to meet both current and future needs.