In the dynamic world of printing, the demand for high-quality, durable, and versatile solutions has never been greater. One technology that stands out is the PVC gravure printer, a cornerstone in the production of premium printed materials on PVC substrates. Whether you’re producing packaging, signage, or decorative films, this innovative machinery offers unmatched precision, speed, and adaptability.

What Sets PVC Gravure Printers Apart?

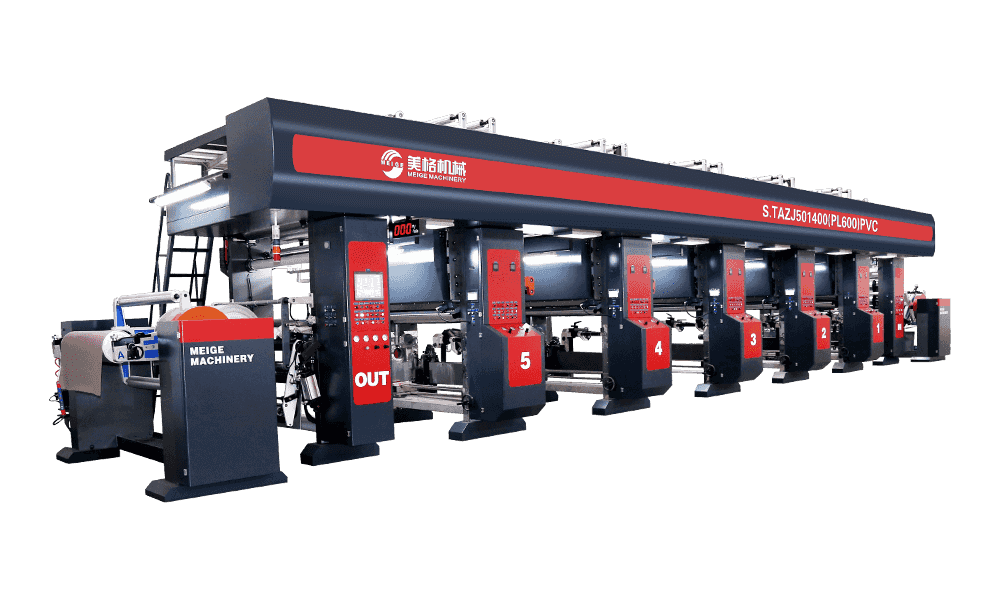

At its core, a gravure printer operates using an engraved cylinder to transfer ink onto a substrate. When applied to PVC materials, this method ensures rich color saturation, sharp details, and consistent results over long print runs. The process involves etching the design into the cylinder’s surface, which is then coated with ink. Excess ink is wiped away, leaving only the engraved areas filled. As the PVC material passes through the printer, the ink is transferred directly onto its surface under controlled pressure and temperature conditions.

What makes PVC gravure printers particularly appealing is their ability to handle a wide range of PVC thicknesses and textures. From rigid boards to flexible films, these printers deliver exceptional adhesion and durability, ensuring that prints remain vibrant even under challenging environmental conditions.

Applications Across Industries

The versatility of PVC gravure printers has made them indispensable across various industries. In packaging, they are widely used for creating eye-catching designs on food wrappers, cosmetic containers, and pharmaceutical labels. Their ability to produce intricate patterns and gradients makes them ideal for brands seeking to stand out on crowded shelves.

In the realm of construction and interior design, PVC gravure printers excel at producing decorative laminates, flooring, and wall panels. These applications require not only aesthetic appeal but also resistance to wear and tear—qualities that gravure printing delivers effortlessly.

Signage and advertising also benefit immensely from this technology. Outdoor banners, vehicle wraps, and promotional displays printed on PVC using gravure techniques boast superior UV resistance and weatherproofing, ensuring longevity and impact.

Advantages Over Other Printing Methods

Compared to other printing technologies like screen or digital printing, PVC gravure printers offer distinct advantages. For one, they are highly efficient for large-scale production, making them cost-effective for bulk orders. Additionally, the engraved cylinders allow for precise replication of complex designs, something that can be challenging with alternative methods.

Another notable benefit is sustainability. Modern PVC gravure printers are designed with eco-friendly practices in mind, minimizing ink waste and energy consumption. This aligns perfectly with the growing emphasis on environmentally responsible manufacturing processes.