Rotogravure printing operates on a unique engraving process where images are carved onto a cylinder, which then transfers the ink to the substrate. Unlike offset or screen printing, which involve flat or mesh printing surfaces, rotogravure printing uses a cylinder to provide a continuous, rotary print. This difference in process enables rotogravure to achieve higher speeds, more detailed prints, and better ink coverage.

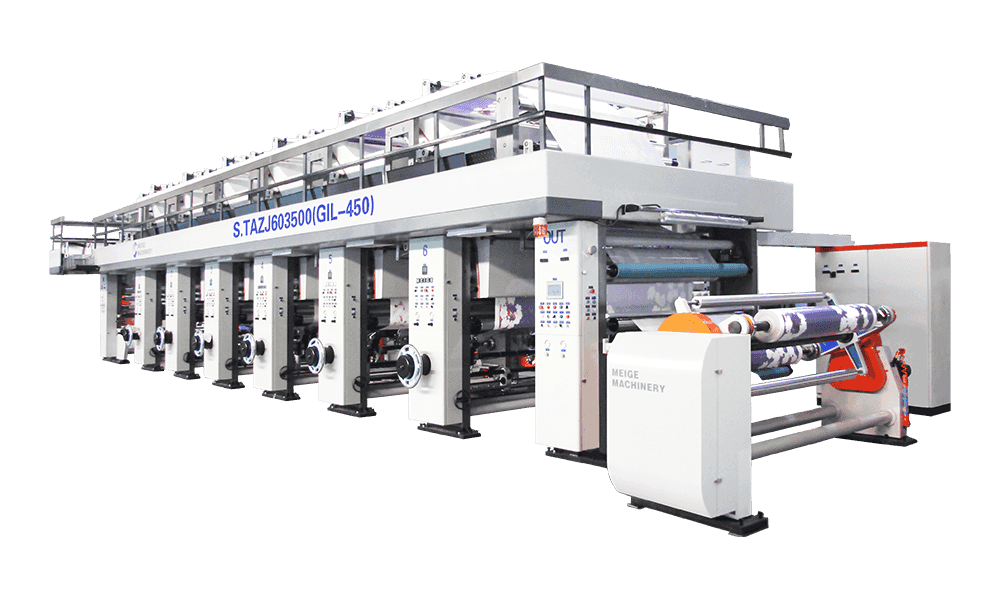

The main components of a rotogravure printing machine include the engraving cylinder, ink system, doctor blade, and drying system. Each of these elements works in tandem to create the high-quality printed material that rotogravure is known for.

Key Advantages of Rotogravure Printing Machines

Exceptional Print Quality

One of the most significant benefits of rotogravure printing is the superior quality it delivers. The engraved cylinders allow for a high degree of detail and clarity, making it ideal for printing images with fine lines, gradients, and photographic detail. The print quality is consistent across large volumes, which is particularly beneficial for applications like packaging, magazines, and catalogs, where vibrant colors and precise image reproduction are essential.

High-Speed Production

Rotogravure printing machines are designed for high-speed production, capable of printing large quantities in a short amount of time. This speed is one of the key reasons rotogravure is favored in industries where high-volume, fast-paced production is essential. Whether producing flexible packaging, labels, or wallpaper, the ability to print at speeds of thousands of meters per hour ensures that manufacturers can meet tight deadlines and reduce production time.

Cost-Effectiveness for Large Volumes

While the initial investment in a rotogravure printing press may be higher compared to other printing methods, the process becomes increasingly cost-effective as production volumes rise. The efficiency of rotogravure in high-volume runs allows manufacturers to take advantage of economies of scale. Once the machine is set up, it can run at full capacity for extended periods without requiring significant downtime, lowering the per-unit cost of printed materials.

Ability to Print on Diverse Substrates

Rotogravure printing is incredibly versatile, capable of printing on a wide range of materials. Whether it’s paper, plastic film, metal foil, or synthetic materials, rotogravure can handle different substrates without compromising on quality. This flexibility makes rotogravure an excellent choice for manufacturers in various industries, including food packaging, pharmaceuticals, textiles, and more.

Better Ink Transfer and Durability

The engraved cylinder in a rotogravure printing press provides superior ink transfer, ensuring that the ink is evenly distributed across the substrate. This feature helps achieve even color distribution, sharp lines, and smooth gradients, which are vital for high-quality prints. Additionally, rotogravure prints tend to be more durable than those created by other methods, as the ink adheres better to the substrate and is less likely to smudge or fade.

Flexibility in Print Design

Rotogravure offers a high degree of flexibility in terms of print design. The ability to engrave intricate images, detailed logos, and complex patterns allows designers to experiment with a wide range of designs. This makes rotogravure ideal for industries that rely on visually appealing packaging or promotional materials. Brands can use rotogravure to create eye-catching prints that attract consumer attention, providing a competitive edge in the market.