The Versatility of Gravure Printing

One of the defining characteristics of gravure printing is its versatility. This printing method can be used across a wide array of industries, providing excellent results for both high-end and everyday products. Some of the most common applications of gravure printing include:

Packaging: Gravure printing is most commonly used in the packaging industry. It excels in producing high-quality images on flexible packaging materials like plastic, foil, and paper. Food products, cosmetics, and beverages often utilize gravure-printed packaging to ensure their product stands out on store shelves.

Textiles: The textile industry relies heavily on Gravure printer for its ability to reproduce intricate designs on fabrics. Clothing brands, home décor manufacturers, and upholstery makers often turn to gravure for vibrant prints that require fine detail and color accuracy.

Magazines and Newspapers: While digital printing is making its mark in the publishing industry, gravure printing is still widely used for large print runs of magazines, catalogs, and newspapers. The high-speed nature of the process makes it ideal for mass printing.

Decorative Printing: From wallpaper to wrapping paper, gravure printing is also used for decorative applications. Its ability to handle multi-colored designs and detailed patterns gives it an edge in creative industries.

Technological Advancements in Gravure Printing

Over the years, gravure printing has seen several technological advancements that have improved both its quality and efficiency. For example:

Laser Engraving: Traditionally, gravure cylinders were etched by hand or with chemical processes. Now, laser engraving has revolutionized the process, allowing for faster, more precise engravings with better control over the depth and sharpness of the image. This advancement has led to improved image quality and consistency.

Eco-Friendly Inks and Solvents: Environmental concerns have pushed the printing industry to adopt more sustainable practices. In response, gravure printing has shifted towards the use of eco-friendly inks and solvents, which reduce harmful emissions and make the process more environmentally responsible.

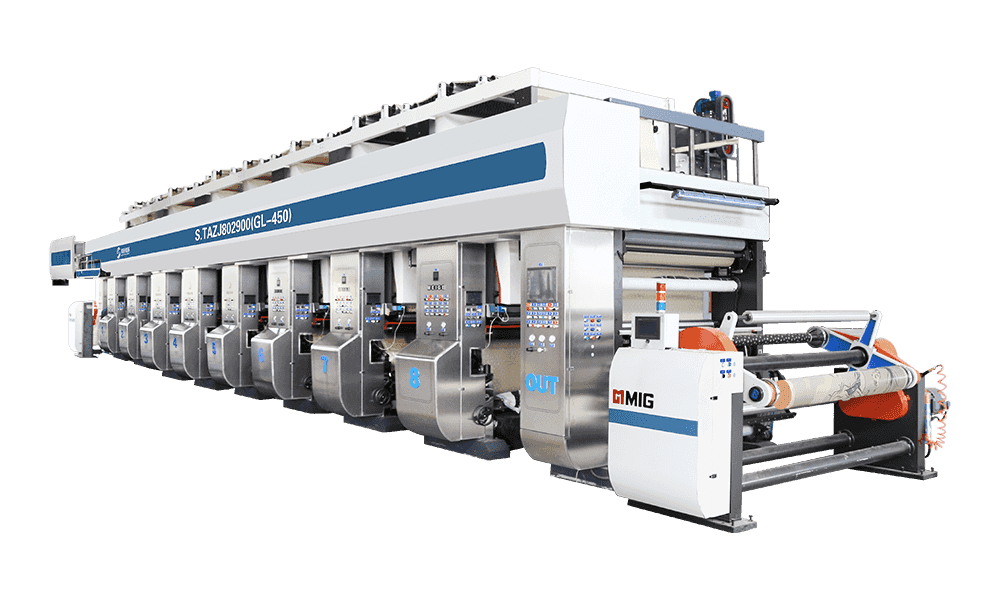

Automation: Modern gravure presses are highly automated, allowing for faster setup times, less human error, and greater consistency. Automation also contributes to cost savings and improved productivity, making gravure more competitive in the printing world.

Gravure vs. Other Printing Methods

When compared to other popular printing methods like flexography and offset, gravure has distinct advantages that make it the preferred choice for certain applications:

Higher Quality for Long Runs: While offset printing is great for short runs, gravure excels in producing high-quality prints for longer runs. Its deep-cell engraving allows for superior color reproduction, which makes it ideal for packaging that requires a high level of detail and color accuracy.

Superior to Flexo for Fine Details: Flexographic printing is often used for packaging, but it struggles with fine details and gradients. Gravure printing, on the other hand, is capable of achieving a much higher level of detail, making it the preferred option for luxury packaging and decorative prints.