Emerging Trends in Rotogravure Printing

The rotogravure printing industry is experiencing several key trends that are shaping its future:

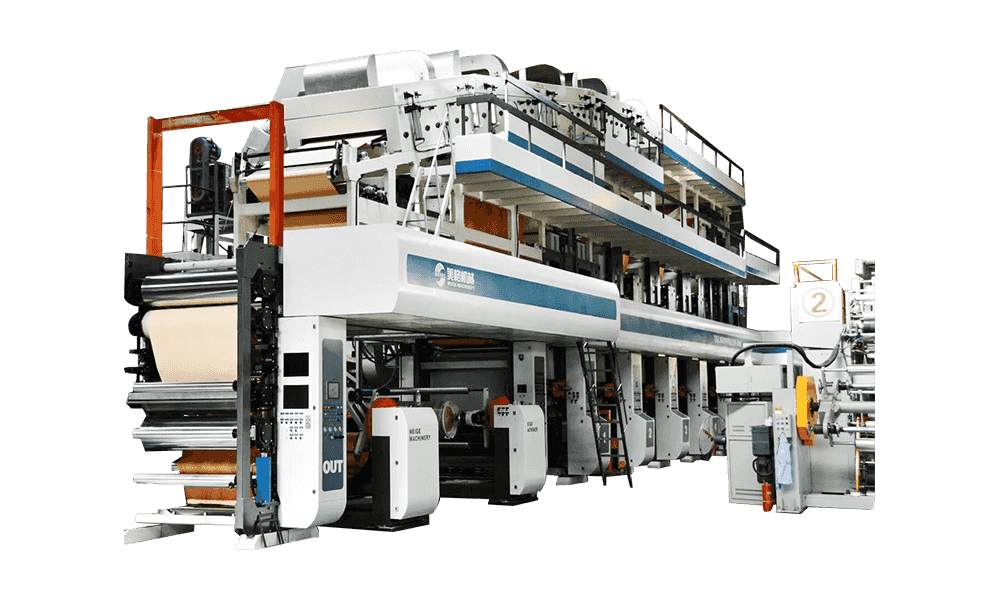

Automation and Smart Technology: Automation is becoming a critical aspect of modern rotogravure printing machines. New systems are incorporating smart sensors and AI-driven technology to optimize printing processes. These advancements allow for more precise control over ink application, color consistency, and cylinder alignment, reducing manual intervention and minimizing errors.

Improved Cylinder Engraving Techniques: Advances in cylinder engraving technology, such as laser engraving, are enhancing the quality and precision of rotogravure printing. These improvements allow for greater control over cell depth and distribution, resulting in sharper images and better color reproduction. Laser engraving also speeds up the cylinder production process, enabling faster turnaround times for print jobs.

Hybrid Printing Solutions: To meet the growing demand for shorter print runs and customization, some manufacturers are developing hybrid printing machines that combine the strengths of rotogravure with digital printing capabilities. This allows companies to enjoy the high-quality output of rotogravure while leveraging the flexibility and speed of digital printing for shorter runs.

Innovations in Sustainable Printing

Sustainability is becoming a central focus in the printing industry, and rotogravure printing is no exception. Several innovations are helping to make the process more environmentally friendly:

Eco-Friendly Inks: Traditional solvent-based inks used in rotogravure printing are being replaced with water-based or UV-curable inks. These eco-friendly inks reduce harmful emissions, improve worker safety, and decrease the overall environmental impact of printing.

Energy Efficiency: Modern rotogravure machines are designed with energy-saving features, such as improved drying systems that use less energy to cure inks. Additionally, many machines are equipped with energy-efficient motors and control systems that minimize power consumption during printing.

Recyclable and Biodegradable Substrates: In response to the growing demand for sustainable packaging, rotogravure printing is increasingly being used on recyclable and biodegradable materials. These substrates offer the same high-quality print results as traditional materials but with a significantly reduced environmental footprint.

Waste Reduction: New technologies are enabling more precise control over ink usage, reducing waste during the printing process. Additionally, automated quality control systems help identify defects in real-time, preventing misprints and minimizing the amount of discarded material.

Benefits of Rotogravure Printing in the Modern Era

While innovations are transforming the landscape, the core benefits of rotogravure printing machines remain highly relevant in today's manufacturing environment:

High Resolution and Detail: Rotogravure's ability to reproduce intricate images with fine lines and sharp detail makes it ideal for packaging designs that require vibrant, eye-catching visuals. This capability is particularly valuable in industries like food and beverage, where packaging plays a crucial role in marketing and branding.

Long-Lasting Durability: Rotogravure printing cylinders are known for their durability and longevity. Unlike some other printing processes, the engraved cylinders can be used repeatedly for large print runs without significant degradation, making it a cost-effective option for long-term production.

Consistent Color Quality: Rotogravure printing excels in maintaining color consistency throughout the printing process. This is essential for brands that require uniformity across all printed materials, such as packaging, promotional materials, and labels.

Large-Scale Efficiency: For high-volume production, rotogravure remains one of the most efficient printing methods. The ability to print continuously on large rolls of material makes it well-suited for industries that require rapid production, such as packaging and commercial printing.