Enhanced Product Durability

One of the most significant advantages of using a PVC Laminating Embossing Machine is the improved durability of the final product. The embossing process enhances the physical properties of the PVC film, making it more resistant to wear, scratches, and environmental damage. For example, embossed PVC laminates used in furniture and automotive industries have enhanced surface hardness, which prolongs the life of the product and reduces maintenance costs.

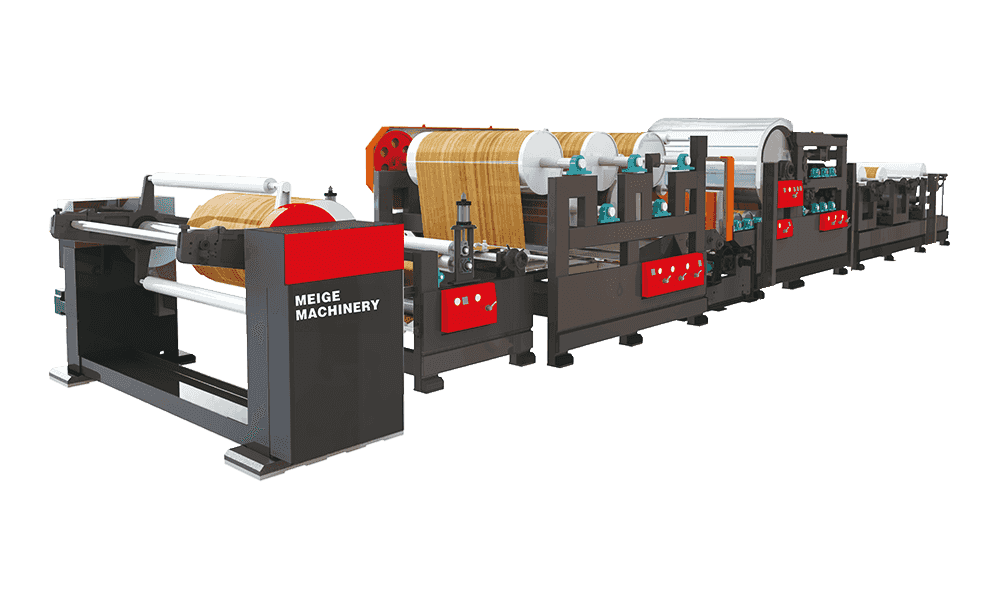

Aesthetic Versatility and Customization

The ability to create customized textures and patterns on PVC sheets is another crucial benefit. Embossing allows manufacturers to add intricate patterns, such as wood grain, leather texture, or geometric designs, directly onto the surface of the PVC. This flexibility makes PVC Laminating Embossing Machines invaluable in industries like furniture, fashion, automotive, and packaging, where design plays a key role in the appeal of the final product.

With multiple embossing rollers, manufacturers can produce various patterns without changing the entire machine setup. This saves time and reduces production costs. Additionally, the ability to laminate multiple layers of material allows manufacturers to create PVC products with different finishes, such as matte, glossy, or textured surfaces.

Cost Efficiency

Although the initial investment in a PVC Laminating Embossing Machine may be significant, the long-term cost savings are undeniable. By combining the embossing and laminating processes in one machine, manufacturers can save on labor, space, and time. Furthermore, the high-speed operation and automation capabilities of these machines ensure that production lines remain efficient, even when dealing with large volumes of product.

Moreover, the energy-efficient design of modern PVC Laminating Embossing Machines helps reduce operational costs over time. Features like adjustable heating systems allow manufacturers to optimize power usage, contributing to both cost savings and sustainability goals.

Versatility Across Industries

From the furniture industry to automotive applications, the PVC Laminating Embossing Machine serves a wide range of sectors. Its ability to work with various materials, including different grades of PVC and other flexible films, makes it highly versatile. Manufacturers in the packaging industry, for instance, use these machines to produce premium packaging materials that enhance the product’s marketability. Embossed PVC packaging is often used for luxury goods, electronics, and cosmetics, where appearance is critical.

Eco-Friendly Solutions

The shift towards sustainability is a growing trend in the manufacturing sector. PVC Laminating Embossing Machines contribute to eco-friendly practices by minimizing waste and improving the overall quality of the product, which can extend its lifecycle. Furthermore, the lamination process can be designed to use less adhesive and other materials, resulting in a reduction in harmful chemical usage.