-

Intelligent manufacturing automation, digitalization

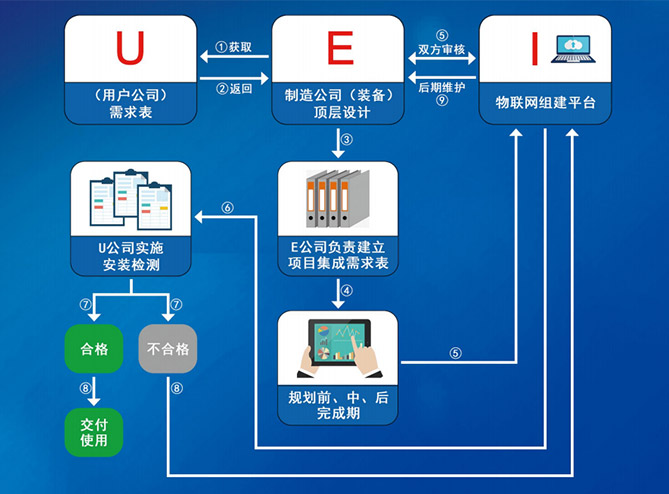

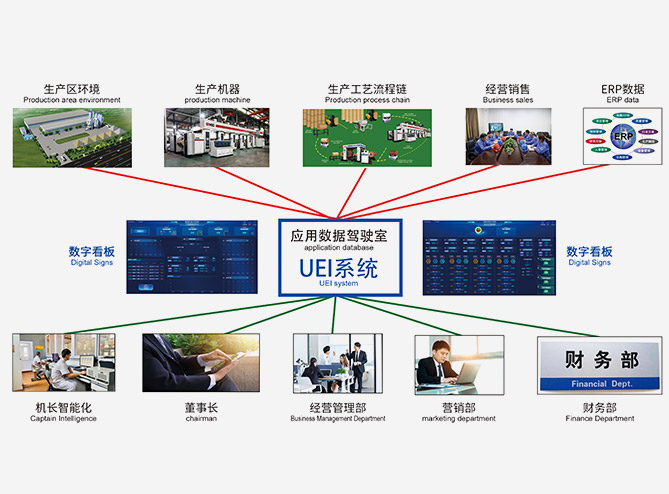

of production processes, industry firstsUEI Scheme Operation Flow

This project is based on the needs of printing machinery user U, printingmachinery equipment manufacturing enterprise E, and Internet of Thingsplatform 1. With printing machinery equipment manufacturing enterprise Eas the core, information collection methods and channels are used to un-derstand the needs of printing machinery user U, and a top-level design isestablished based on E's comprehensive planning to display the require.ments content in a data-driven manner. Then, the Internet of Things plat-form (l) based on U The demand and planning of E enable the interconnec-tion of information content, ultimately achieving intelligent integration of theentire production and business activities.

-

Create digital economy information integrated system

Based printing machinery loT integration and UEl solution expand traditonal industrial digital loT connectivity

Intelligent automation upgrade and innovative design of high-speed printing with supporting robots for automatic loading and unloading of rolls

The disc type dual station rotating frame without serial axis adopts robot docking for loading and unloading

The whole machine adopts data collection and integration with four logo contents, and has a memory scraper to record product codes for restoring the original scraper parameters during reproduction

The innovative development of this machine is mainly prepared for the high-quality development of China's manufacturing industry and digital transformation. -

Automation blockchainn and production quality cost informatization

Library to Library Automation Logistics and Data lnformatization Integration

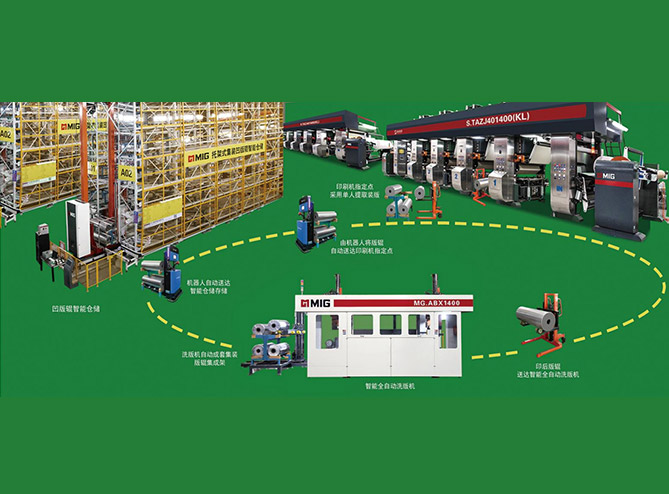

Warehouse-to-warehouse logistics system for gravureprinting decorative roll paper is the concept of whole logisticprocedure of base roll paper transfer from warehouse toprinting machine by AGV and finished decorative roll papertransfer to end product warehouse after printing、rewinding.packing and metering.

This system is consist of decorative base paper withWCS/WMS、finished decorative paper warehouse (ownedby user)、piggyback jack-up docking AGV.automatic loading/unloading apparatus without axial displacement、inte-grated rewinding、packaging and metering machine andelectrical control svstem network.

A library-to-library design specifically designed for digital information transformation and technological upgrading in the printing industry -

Gravure printer gravure cylinder intelligent storage support block chailn

Intelicent Plate Llibrarv for Larae Gravure Printina Machine Roler and Automatic loaistics for ntelicent Fully Automatic Plate Washina Machine

Created a concave roller assembly bracket, improved the inventory conditions of the roller, changed the vertical storage and horizontal use, and changed the logistics from single to complete sets.

AGV taking over roller-carrying by hands can reduce manpower cost as well as plant management cost.

This is improving efficiency of logistics both in warehouseand plant,at the mean time, improving the production effi.ciency of whole enterprise as well.

With effectively connecting with MES system, this will helpto achieve the goal of intelligent plant.

Intelligent Production

Digital integration of production process

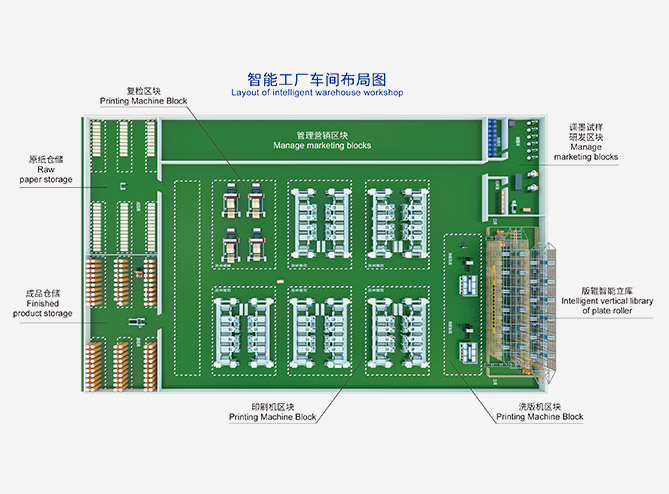

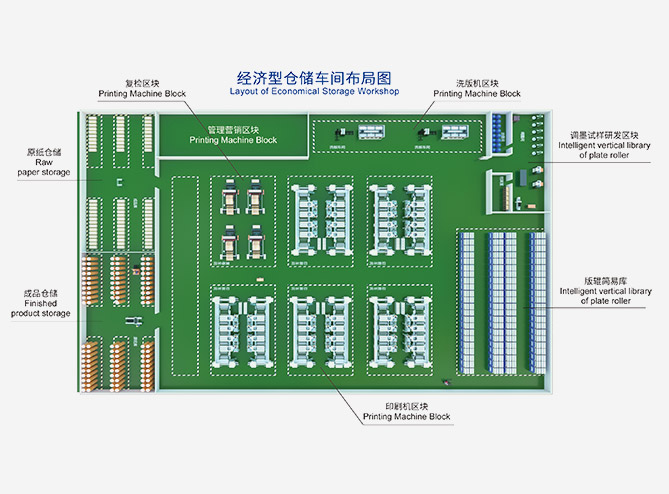

Meige has a digitalized production process, which includes a layout of intelligent factory workshops, an economical warehousing workshop, and a digital cab. We are committed to helping landing users achieve digital transformation of smart factories and testing their actual benefits. At the same time, we actively promote the UEI digital integration and application system, improve production processes, and enhance production efficiency.

The digital collection and real-time display of the four majorblocks connect important management positions to timelypromote deficiencies and change outdated business meth-ods, achieving high-quality development of the informationdigital economy.

-

Layout of intelligent warehouse workshop

-

Lavout of economical storage workshop

-

Digital cab

-

Practical benefits of digital transformation testing for lntelligent factories for landing users

-

UEI digital intelligence integrated system

High Standard Factory

Strict quality control throughout manufacture.

English

English 中文简体

中文简体